| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

FAVORİ GRUP PLASTİK VE MAKİNE SAN. TİC. AŞ.

SELAHADDİN EYYUBİ MAH. 1629. SOK. NO: 3/3 ESENYURT / / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 407 0607

|

Hall: 11

Stand: 1110D

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

In 2010, we have come to life with a young team who is experienced in the plastic industry and has adopted the principle of unconditional customer satisfaction. Established with the purpose of meeting all the machinery and hardware requirements of the sector, Favori Group aims to provide permanent solutions by analyzing the current and future needs of the plastic industry with the efficiency-oriented service concept. Favori Group, which has meticulously selected European, the Far East and Turkish origin brands in its product range, work with the manufacturers who can offer the service to the plastics industry in the fastest way with technology. New Generation Service, Your New Generation Supplier

The slow speed granulator in the GL200 range feature a staggered 200mm diameter rotor with widths ranging from 200 to 450 mm. The rotor is directly driven by a geared motor. The low rotor speed reduces the noise level of the machine and creates less dust while grinding. The special design knives... Product Details The slow speed granulator in the GL200 range feature a staggered 200mm diameter rotor with widths ranging from 200 to 450 mm. The rotor is directly driven by a geared motor. The low rotor speed reduces the noise level of the machine and creates less dust while grinding. The special design knives of the GL series can be sharpened easily and do not need adjustment afterwards. The material is fed via a sound proof feed hopper that can be tailored to fit various applications and feeding ways. Depending on the requirements, the machine can be fit with a wide variety of hoppers, they are mounted on either low or high level base frames with matching suction bins or bag filling adapters. Quick snap fasteners and hand screws make access to the machine for cleaning and maintenance fast and easy. - Direct driven staggered rotor - Special knife design makes adjustment unnecessary - Easy access for maintenance and cleaning - Slow rotor speed creates less noise and dust - Easily customizable to suit different applications The GL200 slow speed granulators of the 200 series are mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues. The resulting granules are then immediately reintroduced into the production process. The machines can be used for rejected products in the online recycling process as well. Different hopper and base frame designs make it possible to integrate the machine with most types of injection molding machines and robots. GL200/200 GL200/300 GL200/400 - V type staged array - Blade can be repeatedly sharpened - Assembling type screen design - Main picture - Screen to be discharged in fast way - Online recycling Previous: GB Series Bottle Granulator Next: GC300 Series Compact Granulator Hot Tags: GL series slow speed granulator, China, manufacturers, suppliers, price, for sale, Online Granulator, Cloth & Silk Shredder, Plastic Granulator, Cardboard Granulator, Wood Granulator, EFS Four Shaft Shredder

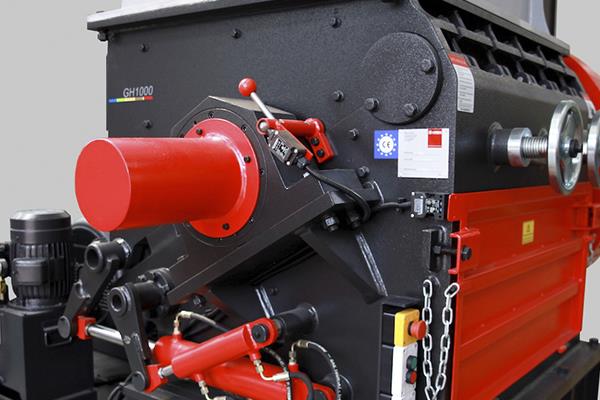

GH700 Series Heavy Duty Granulator The heavy duty granulators of the GH series offer a wide array of different rotor designs with widths ranging from 700 mm to 2000 mm with a diameter of 500 and 1000 mm. The completely welded heavy steel construction is designed to withstand the most demanding and universal applications. Rotor... Product Details The heavy duty granulators of the GH series offer a wide array of different rotor designs with widths ranging from 700 mm to 2000 mm with a diameter of 500 and 1000 mm. The completely welded heavy steel construction is designed to withstand the most demanding and universal applications. Rotor bearings, knife mounts and rotor shaft are oversized. The standard V-cut creates a high quality regrind with a very low percentage of fines in the output material. The removable third stator blade is acting as a deflector wedge and allows the machine to be quickly adjusted to different application scenarios. Other standard features include easily replaceable wear plates in the cutting chamber as well as outboard bearings reducing the risk of contamination. External knife design Special designed deflector for machine wide application Multiple rotor designs Proven machine housing designs Everlasting and firm of welded steel construction The wide range of rotors and hopper styles allow the GH machines to be tailored to almost every application in the plastic recycling field. The GH series granulators are mainly used as large central granulators for in house recycling applications to process large thick walled parts in one step or as a second step granulator after a shredder to reach higher throughput rates. When used to grind light materials, such as bottles the throughput can be greatly increased with the addition of ENMA force feeding device. For abrasive, contaminated or highly filled materials the machines can be equipped with special wear protections, such as hard facing of the rotor and housing and key parts manufactured from highly wear resistant steels. GH700/700 GH700/1000 GH700/1200 GH800/1400 GH800/1600 GH800/2000 - Everlasting and firm of welded steel construction - Conveyor + Shredder + Granulator + Collection - Universal rotor - Add the third set of stator blades for the large solid material - Design of heavy-duty rotor - Suitable for crushing large loosen material Previous: GE500 Series Economy Granulator Next: GP Sereis Pipe.profile.sheet Granulator Hot Tags: GH700 series heavy duty granulator, China, manufacturers, suppliers, price, for sale, Sheet & Board Shredder, Cardboard Granulator, Online Granulator, Pallet Shredder, Wood Shredder, Single Shaft Shredder

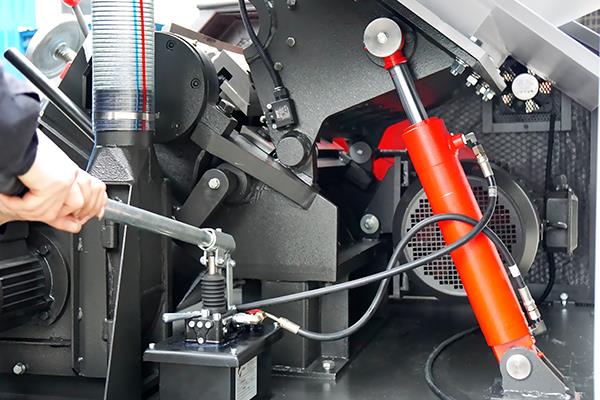

GE500 Series Economy Granulator GE series economy granulator adopts high efficiency double-scissors cutting technology of rotor. GE500 series has various of rotor type available, width ranging from 500 to 2000mm with diameter of 500mm. The whole welded steel structure and the V-shaped rotor design. Product Details GE series economy granulator adopts high efficiency double-scissors cutting technology of rotor. GE500 series has various of rotor type available, width ranging from 500 to 2000mm with diameter of 500mm. The whole welded steel structure and the V-shaped rotor design. It is suitable for the recycling of many kinds of materials, running smoothly and reliably. GE500 series granulator is equipped with manual or hydraulic box opening system, which easy to open and clean, to maintain the crushing chamber, so as to adjust and fix the blades, clean and replace screen. The series is with the latest developed soundproof material hopper, reliable technology and sound insulation effect. - Sprue gatings - On-line waste - Small lumps - Waste paper - Pipes - Films - Urban waste GE series is used economically for handling the defects during injection molding, sprues, pipes, profiles, sheets, films and nozzles. It is everlasting and easy to clean with longer life. ENMA s reliable V-shaped cutting technology not only retains all the advantages of the original cross-cutting technology, but also has new characteristics. Cutting point only at the place where the blades cross instead of the whole blade. It considerably ensures lower noise, less powder and prolongs the service life, thus saving the energy. V -cutting technology drives the materials towards the centre of the rotor and solves the problems such as stacking materials inside, heat from rubbing and excessive side-wall friction. GE500/500 GE500/700 GE500/1000 GE500/1400 - Electrical type of hydraulic opening system - Multi-knife cutting type - Machine design of open type - Conveyor + Granulator + Suction system - S-Universal type rotor - H-Heavy duty rotor Previous: No Information Next: GH700 Series Heavy Duty Granulator Hot Tags: GE500 series economy granulator, China, manufacturers, suppliers, price, for sale, Plastic Granulator, ELS Light Shredder, Paper Granulator, Single Shaft Shredder, Wood Pallet shredder, Wood Shredder

GP Series Pipe, Profile, Sheet Granulator The pipe granulator of GP series are available in rotor width of up to 1000mm and diameter ranging from 500, 700, 800 to 1000mm. The completely welded heavy steel cutting chamber is angled and fitted with an extended hopper to allow easy feeding of parts. Product Details The pipe granulator of GP series are available in rotor width of up to 1000mm and diameter ranging from 500, 700, 800 to 1000mm. The completely welded heavy steel cutting chamber is angled and fitted with an extended hopper to allow easy feeding of parts. Convenient and quick of knives being adjusted outside of machine Specially designed for pipe Wide choice of rotors Well thought out housing design Strong welded steel construction Oversized outboard bearings GP series is specially designed for crushing PE, PP, PVC pipes with diameter from 16mm to 450mm. Conveyor belt, blower fan, storage silo and dust collection system are available for higher output. Conventional granulators have substantial problems handing long pipes. To feed large and bulky parts in most cases cavities or platforms are needed. Therefore, ENMA develop the GP series granulator. Thanks to the almost horizontal feeding hopper, long pieces can be fed easily. While the machine is operating, there is no risk of blocking. In case of congestion no more material will be accepted by the machine until the grinding chamber is empty and the machine will accept material again, and work continuously. GP500/500 GP700/700 GP800/800 GP1000/800 The standard V-cut creates a high quality regrind with a very low percentage of fines in the output material. Other standard features include anti-wear plate that is easily disassembled in the broken chamber, outboard bearings reducing the risk of contamination. Previous: GH700 Series Heavy Duty Granulator Next: GS300/500 Series Sound Proof Granulator Hot Tags: GP sereis pipe.profile.sheet granulator, China, manufacturers, suppliers, price, for sale, Blow Moulding Granulator, EFS Four Shaft Shredder, Granulator Screen, Sheet & Board Shredder, Granulator Spare Parts, Pulverizer

GB Series Bottle Granulator GB series granulator is a special bottle granulator with high output and low energy consumption designed by ENMA. The output can reach 500KG-6000KG/H. The granulator offers a wide array of different rotor designs with widths ranging from 700 mm to 2000 mm with a diameter of 700mm. Product Details GB series granulator is a special bottle granulator with high output and low energy consumption designed by ENMA. The output can reach 500KG-6000KG/H. The granulator offers a wide array of different rotor designs with widths ranging from 700 mm to 2000 mm with a diameter of 700mm. The completely welded heavy steel construction is designed to withstand the most demanding and universal applications. Oversized rotor bearings, knife mounts and rotor shaft are equipped. The standard V-cut creates a high quality regrind with a very low percentage of fines in the output material. The removable third stator blade is acting as a deflector wedge and allows the machine to be quickly adjusted to different application scenarios. Other standard features include easily replaceable wear plates in the cutting chamber as well as outboard bearings reducing the risk of contamination. Convenient and quick external knife adjusting design Special designed deflector for machine wide application Multiple rotor designs Proven machine housing design Everlasting and firm of welded steel construction The wide range of rotors and hopper styles allow the GB series granulator to be tailored to recycling of normal PET bottle, PP/PE bottle. The GB series granulator is patented PET granulator of ENMA, which can be equipped with special wear protections, such as hard facing of the rotor, housing and key parts manufactured from highly wear resistant steels. GB700/700 GB700/1000 GB700/1200 GB700/1400 GB700/1600 - Parallel screw force feeding - Design of external bearing - Rotor of dual-scissor cutting - Hydraulic system of granulator chamber opening - Screw feeding quantity upon output quantity - Rubber sealing system of integral chamber, for crushing with water Previous: GS300/500 Series Sound Proof Granulator Next: GL Series Slow Speed Granulator Hot Tags: GB series bottle granulator, China, manufacturers, suppliers, price, for sale, Household Waste Shredder, Sheet & Board Granulator, GL Series Slow Speed Granulator, Medium Sized Granulator, Household Electrical Appliances Granulator, Injection Moulding Granulator

GS300/500 Series Sound Proof Granulator The GS compact/sound proof granulators are designed with a complete sound proof enclosure resulting in an extremely quiet operation. Different rotor designs are available in widths ranging from 300 mm to 1400 mm with a diameter of 300 mm. The completely welded cutting chamber in conjunction with... Product Details The GS compact/sound proof granulators are designed with a complete sound proof enclosure resulting in an extremely quiet operation. Different rotor designs are available in widths ranging from 300 mm to 1400 mm with a diameter of 300 mm. The completely welded cutting chamber in conjunction with the V type rotor design ensures dependability in operation and universal application use. While it delivers excellent sound proofing capabilities, it still offers easy and quick access to the cutting chamber during rotor and stator knife changes, servicing or screen changes. The sound dampening material used in these machines is based on the latest technological research. Knives are adjusted outside of the machine Compact design Different rotor types available Soundproofed housing Strong tangential infeed The cutting geometry of the GS series allows even voluminous materials to be ground. The complete GS series line achieves a high quality regrind independent of the material type or form such as injection moulding parts, blow moulding parts, profiles, sheets, film, etc. The 300 series GS machines are mainly used in inline operations for processing of rejected products, or runners and sprues. The small footprint and easy movability make the machines very easy to place in existing operations. GS300/300 GS300/600 GS300/1000 GS300/1400 GS500/500 GS500/700 GS500/1000 GS500/1400 - Security devices are the top concern of ENMA - Compact type design - Manual hydraulic opening device - Design of integral type control cabinet - Design of discharge without bridged - Heavy duty rotor Previous: GP Sereis Pipe.profile.sheet Granulator Next: GB Series Bottle Granulator Hot Tags: GS300/500 series sound proof granulator, China, manufacturers, suppliers, price, for sale, Wood Shredder, Cardboard Granulator, Shredder Motor, Shredder, Household Waste Shredder, Small Sized Granulator

ELS Light Shredder ELS series shredder is single shaft shredder with a tangential in-feed to eliminate the need for a hydraulic feeding system. The space saving and maneuverable design combined with the plug and play controls make this machine very flexible and ready to go in no time. Product Details ELS series shredder is single shaft shredder with a tangential in-feed to eliminate the need for a hydraulic feeding system. The space saving and maneuverable design combined with the plug and play controls make this machine very flexible and ready to go in no time. Comparing with EMS series, it is equipped with outboard bearing, 250 mm diameter flat E rotors with 600 or 800 mm width driven by an oversized geared motor. Utilizing the proven ENMA knife holder and knife design. The user friendly design makes cleaning and maintenance work a breeze. The low speed of 60 rpm combined with the compact design of ELS shredder makes it possible to shred lumps at a relatively low noise level. The machines can be fed manually or by conveyor, material discharge can be done via conveyor or into a drop box. Affordable solution for small lumps, economic and practical Simple upgrade for existing granulation system Easy to move and place Tangential in-feed avoids the need for a hydraulic pusher Small footprint Low power consumption ELS shredder has been designed for in house recycling of small lumps and purges from injection and blow molding processes. The typical input materials are small and medium sized parts such as lumps. The material can be shred to reduce the volume or processed further in a granulator to be reintroduced into the production process immediately. The machine also can be used to destroy sensitive products or to recycle small batches of low volume products to avoid contamination of the main product line. ELS600 ELS800 - V type knife design - Direct connection driving - Adjustable hydraulic system - Small sized lumps solution - Screw outputting device is available - Even and ordered outputting Previous: No Information Next: EMS Medium Sized Shredder Hot Tags: ELS light shredder, China, manufacturers, suppliers, price, for sale, Bottle Granulator, Cable Granulator, Copper Wire Granulator, Rubber Shredder, Household Electrical Appliances Granulator, Plastic Granulator

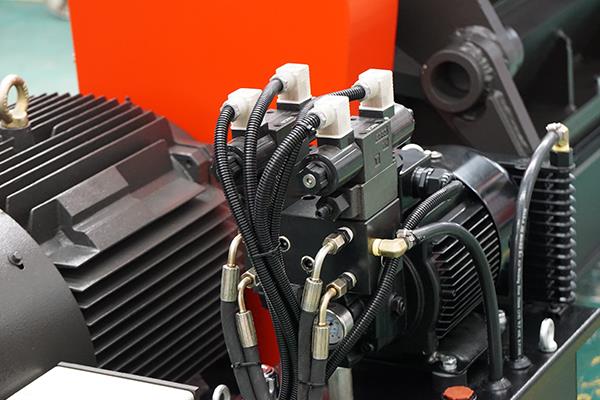

EMS Medium Sized Shredder EMS shredder is single shaft shredder with a powerful two speed swing ram design eliminating the risk of blocking and wearing out of internal guide rails. The machine is very versatile and can be used for shredding of all kinds of input materials and is well suit for different industries. Product Details EMS shredder is single shaft shredder with a powerful two speed swing ram design eliminating the risk of blocking and wearing out of internal guide rails. The machine is very versatile and can be used for shredding of all kinds of input materials and is well suit for different industries. The 450mm diameter rotors ranging form 1000mm to 2000 mm width are driven by one or two oversized gearboxes. The hydraulic power pack is well integrated into the machine housing to save space and protect it from damage but still easy to access or remove for maintenance. The standard V rotor features the proven ENMA knife and knife holder design, as well as outboard bearings and a hydraulically operated screen cradle are highly appreciated by customer. The machines can be tailored to various applications with cooling or hard facing and other wear options. Low speed, high torque gear driven Powerful hydraulic incline type pusher Open board for easy replacement of cutting blade Easily in-feed with incline pushers Bolted in drive shafts, easy replacement Multiple rotor designs and materials Adjustment speed hydraulic comes standard EMS shredder has been designed for a wide array of applications and industries like in house and general recycling, electronic waste and post consumer waste handling. Input materials can be all kinds of plastics like lumps, pipes, film, woven bags; electronic waste like cables and ICBs, paper, wood and other organic materials. Depending on input material and the following process the shred material as defined by the used screen size can be directly used or go into the next step of size reduction for example in GE series granulator. EMS1000 EMS1300 EMS1600 EMS2000 - Inclined pushing system - Design of open type body makes it easier to replace and clean crushing chamber - High torque Box-type Reducer Driven - Integral screen - High efficiency rotor design Previous: ELS Light Shredder Next: EBS Big Sized Shredder Hot Tags: EMS medium sized shredder, China, manufacturers, suppliers, price, for sale, Granulator Motor, Cable Granulator, EMS Medium Sized Shredder, GH700 Series Heavy Duty Granulator, PP PET Strap Granulator, Granulator Of Recycling

EBS Big Sized Shredder EBS series shredder is single shaft shredder with a large internal volume. The redesigned hydraulic pusher system creates about 35% more space in the cutting chamber while increasing the power and speed of the ram itself. The shredder is equipped with diameter 600mm ENMA effective V type rotor... Product Details EBS series shredder is single shaft shredder with a large internal volume. The redesigned hydraulic pusher system creates about 35% more space in the cutting chamber while increasing the power and speed of the ram itself. The shredder is equipped with diameter 600mm ENMA effective V type rotor with width ranging from 1000mm to 2500mm. The rotor is driven via an oversized gearbox. The completely closed welded steel housing increases the stability and avoids material spillage. EBS inherits all of the advantages of the ENMA knife and knife holder design as well as standard features such as outboard bearings, hydraulic screen cradle, it s easy maintain ability and advanced controls. 35% more internal volume compared to the first generation of EBS series Internal hydraulic pusher Variable faster pusher movement Smaller footprint compared to traditional shredder with horizontal pusher Opening housing body makes changing and cleaning blade easily Multiple rotor and blade section Choosing different size blades upon different materials EBS series shredder is designed to meet the requirements of waste recovery in various industries, including general waste recovery, electronic waste recovery and domestic waste recycling, etc. There are a wide variety of recyclable materials, such as various plastic products, including bulk materials, etc. Pipes, films, woven bags, and all kinds of electronic cable scrap, ICB buckets, waste paper, used wood and various organic materials. According to the crushing materials and the next step of processing needs to choose the appropriate size of sieve mesh to determine the size of the recycled material, Some materials can be directly recycled after shredding, others can be transported to GH series granulator and other equipment for further refinement. EBS1200 EBS1600 EBS2000 EBS2500 - High efficiency universal rotor - Convenient knife exchanging design - Adjustable hydraulic system - Adjustable feeding system - Wearable rotor - Complete design Previous: EMS Medium Sized Shredder Next: EPS Shredder for Large Pipe Hot Tags: EBS big sized shredder, China, manufacturers, suppliers, price, for sale, Granulator Blade, GC300 Series Compact Granulator, Paper Granulator, Granulator Motor Belt, PVC Pulverizer, Sheet & Board Shredder

EPS Shredder for Large Pipe EPS shredder is the global first and registered single shaft shredder able to handle large diameter pipe up to 1200mm without the need for pre-cutting. Since their introduction they became the super star standard for pipe shredding and are used by threading pipe manufactures all over the world.... Product Details EPS shredder is the global first and registered single shaft shredder able to handle large diameter pipe up to 1200mm without the need for pre-cutting. Since their introduction they became the super star standard for pipe shredding and are used by threading pipe manufactures all over the world. More than 150 installations demonstrate our technological leadership in this industry and continuing innovation based on market demands and customer feedback. Depending on the pipe diameter the EPS rotor diameter and width range from 800mm to 1500mm. The standard hopper fits all pipe lengths of up to 3-6m. The combination of advanced control, low rotor speed and smooth hydraulics create a reliable and easy to use system. Handle large diameter pipes up to 1200mm without pre-cutting Low power consumption Bundle of smaller pipes be fed Automation operation, high security High output Big diameter root(Max. to 1500mm) The main focus of the EPS shredding of large diameter pipes or bundles of smaller pipes and profiles made from HDPE, PP and all kinds of PVC. Furthermore, the machine can be used for recycling of other plastic parts, such as large lumps, stacked wheelie bins and pallets. In combination with other ENMA size reduction equipment such as granulator and pulverizer, we are able to provide a complete turn key recycling solution. EPS800 EPS1000 EPS1200 - Complete pipe recycling system - Size reduction of large caliber pipe - Dual-driving - Hydraulic automatic security plate - Hydraulic opening safety door system - Adjustable hydraulic propulsion system Previous: EBS Big Sized Shredder Next: No Information Hot Tags: EPS shredder for large pipe, China, manufacturers, suppliers, price, for sale, Granulator Motor, ELS Light Shredder, Film Shredder, Granulator Screen, Wood Pallet shredder, GH700 Series Heavy Duty Granulator

The company has no registered brand information.

TR

TR