| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

FEYDAŞ MAKİNA VE MÜHENDİSLİK LTD. ŞTİ.

Yeşiloba Mah. Mehmet Başpınar Orta Ölçekli Sanayi Sitesi 46249 Sokak No: 20 / Seyhan / ADANA / TÜRKİYE

|

Contact Info: +90 322 428 0145

|

Hall: 11

Stand: 1116B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Founded by Fehmi Yoldas, Feydas Machinery and Engineering Ltd. Sti. has expanded its economy in the field of machinery and engineering for more than 38 years and has made great progress by developing itself especially in the production of Plastic Recycling Machines. Feydas Machinery is the first company that established the after sales service and maintenance in the plastic recycling machinery manufacturing sector in Turkey.

The Agglomerated Granule Machine is designed to granulate at high capacity and efficiency to crush, mix, dry and condense waste plastics to be recycled, by feeding extruder screw at required performance.

The Automatic Filter system -which is used in continuous and high efficient machinery- is mainly used to increase the cleaning efficiency and the quality of the material. Also it reduces labor costs and electricity costs. Thanks to its high filtration rate the pressure and the electric consumption of the main engine/motor reduces greatly. This provides energy saving.

The humidity of the material coming out of the drying-squeezing is less than 3%. Operates automatically, saves manpower cost & electricity cost by 30 %. Squeezed and dried material is sent directly to extruder to become granules. Operating 365 days/24 hours, it increases the capacity, reduces maintenance cost. The feeded recycled materials are squeezed to become flakes or lumps. After being squeezed, these lumps or flakes with much lower moisture and higher density can be directly fed into pelletizing extruder. Feydaş single screw squeezer saves cost, energy and time. It helps to protect environment and increase productivity as well as efficiency. 20

Die Face Cutter is used to turn into granules from the plastic raw material. It is a very useful machine part especially in plastic products of high efficiency machines.

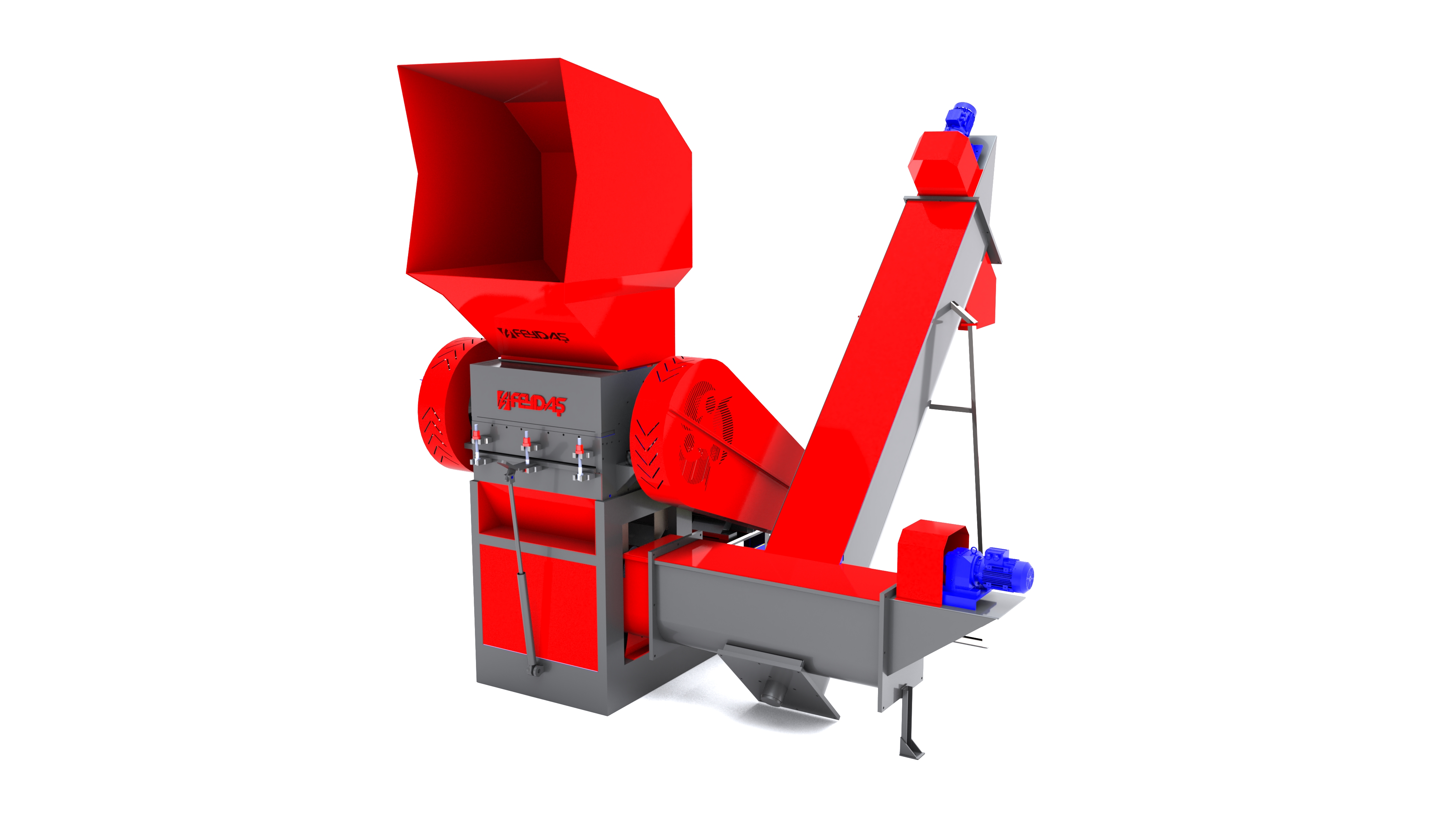

The Crushing Machine is designed with the highest engineering quality to withstand high performance over a long period of time. The duty of this machine is to crush waste plastic materials into small pieces and prepare them for the next operation. The water mechanism we have installed in it, provides a clean and high quality product. Our Crushing machines are designed for different tasks according to the demands of our customers and the dimensions of the production line. Different rotor sizes and dimensions determine the power of our crushing machine and with these dimensions; such as 60, 80, 100, 120 and 160 their efficiency varies between 200-2500 kg per hour. Crushing machines are approved by passing all tests and Feydaş Makine provides energy saving in a compact form with assurance and dynamic structure. With its unique compact design, the maintenance is also minimized.

The Granule Machine enables the recycling of waste plastic. It is the last stage of raw material formation. The screw geometry of the Granule Machine is produced with superior Technologies according to the material it is processed. This makes the Granule Machine highly performing and durable. Granule Machine is the most important part of recycling line. This recycling line can optionally be controlled by computer or manually. This system minimizes the chance of operators to make mistakes. The working logic of the Granule Machine is as follows: The raw materials extracted from the agglomeration are melted in the extruder and thrown out with the force of pressure and cut into granules by means of the sieve. Thanks to the water cooling mechanism, collected granules get cooled and with the assistance of silos they are filled in the bigbag sacks. It is the most important stage of producing useful products for human use by preventing the produced granules from causing harm to the environment by recycling them repeatedly.

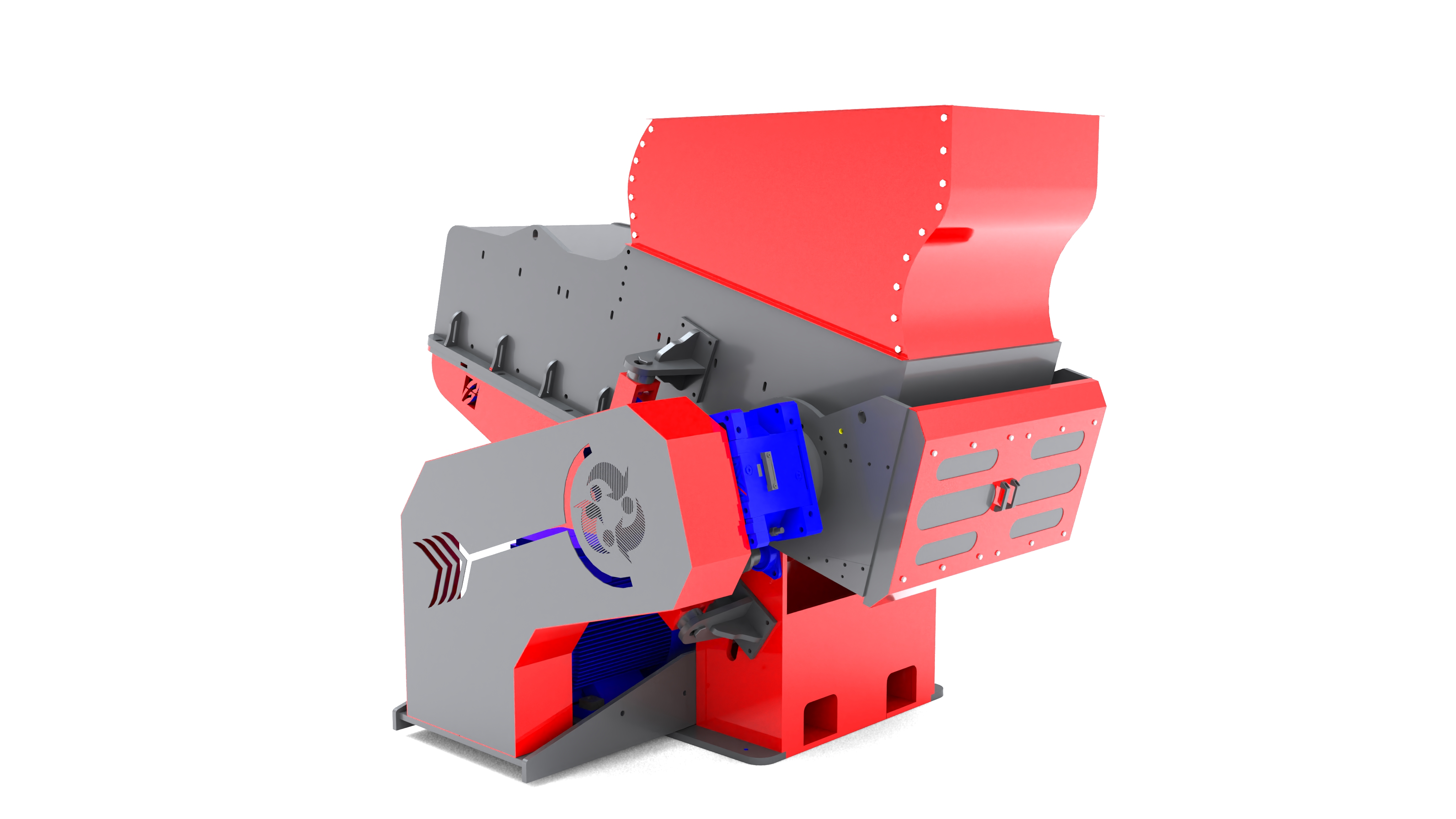

Our Shredder machine is designed with high engineering technology. This machine prepares plastic canisters, plastic bags, nylon, plastic bottles for recycling by shredding them into small pieces. Materials can be placed on the top of the Shredder Machine manually, with a fan or a fork-lift. The materials fall onto the blades of the Shredder . Thanks to powerful motors, these blades shred incoming materials and direct them towards the conveying part. The shredded material can be conveyed by a helix, conveyor or fan. Since the blades of the Shredder are made of special metal, no rust, deterioration or breakage is experienced. Shredder bearing housings are resistant to heavy-duty principles. They have a dust-proof and water-cooling system.

Horizontal Squeezing Machine specially designed by Feydaş Makine applies a mechanical torque and dehydrates the raw material of PE and PP in the form of film and dries to a level of 8% -12% moisture. Horizontal Squeezing Machine has the capacity of 800 - 1000 Kg per hour depending on the system capacity. This machine called Adana Plastic Squeezing has been designed by TUBITAK and turned into a useful model. With this support, Feydaş Makine has enabled the Horizontal Squeezing Machine to reach 800-1000 kg / h yield. Horizontal Squeezing Machine is produced with high performance, fast service and more economical level. The machine chassis is specially designed to withstand strain. The fan used when transferring the extruded material also ensures that the product gets drier during conveying. The Plastic Squeezing machine dehydrates the raw material and ensures better quality of the recycling product.

FEYDAŞ TURBO WASHER is used for cleaning the material, especially processed PE film material, Pet flakes and other hard plastic types. The rotor is dynamically balanced. Roller bearings outside the housing keep the machine operating efficiently. When the material is spilled into the dryer, it is spinned by a rotor operating at high speed. The contaminated particles and water get discharged from the screen holes. The waste water exits from the lower discharge part of the dryer. It plays a major role especially in the disposal of the paper on the product.

The Agglomeration Machine reduces the moisture rate in the plastic and other drying products to zero. Agglomeration Machine, as one of the recycling machines, is a very comprehensive machine in which all the raw materials can be mixed together to ensure high quality and homogeneous product. Boiler bodies of Agglomeration Machines are produced in thicknesses of 10-12 mm and diameters of 100-120-140 cm.

No represented companies found.

The company has no registered brand information.

TR

TR