| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

İNAN GERİ DÖNÜŞÜM SİSTEMLERİ A.Ş.

KAVAKLI İSTİKLAL MAH. 5006. SOK. NO: 9 PK: 34596 / SİLİVRİ / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 280 0376

|

Hall: 11

Stand: 1124

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

İNAN MAKİNE started its first production in a small workshop in Levent Industry area in 1962, today, with its experience of more than half century, produces plastic size reduction machines and recycling washing, drying, extrusion systems needed by national and global plastic manufacturers and recycling companies in its factory with a closed area of 15000 m2. It is positioned among the leading manufacturers in Türkiye and the world. Inan Makine has strengthened its position with its service quality, customer satisfaction, finding modern and technological solutions to meet the changing needs and expectations of its customers, timely intervention to problems, after-sales training and technical services, as well as the guarantee and trust it provides. With the pride of leaving behind half century in the production of these recycling machines, İnan Makine has become an assertive name in the sector and positioned among the best quality manufacturers and continues to offer the solutions needed by the plastics industry without sacrificing quality and principles with its expert staff, manufacturing power, machinery and production technologies. MACHINES AND SYSTEMS MICRONIZER MACHINES, CRUSHER MACHINES, SHREDDERS, WASHING SYSTEMS, DRYING SYSTEMS, TRANSPORT AND STORAGE SYSTEMS. RECYCLING SYSTEMS PET/PET-E BOTTLE AND SHEET CRUSHING/WASHING/DRYING/SCREENING AND STORAGE LINE HDPE/PP CRUSHING/WASHING/DRYING/STORAGE AND GRANULE LINE (BOTTLE, CAP, DRUM, BARREL, etc ) (3D - RIGID PLASTICS) LDPE/LLDPE/PP SHREDDING/WASHING/SQUEENING/STORAGE AND GRANULE LINE (NYLON/STRECH FILM, BIGBAG/SACK, etc ) (2D - SOFT PLASTICS) OUR ACTIVITY AREAS LARGE VOLUME INDUSTRIAL WASTES PLASTIC BARRELS, CASES, PALLETS PLASTIC EXTRUDER WASTES, WEDGES, EDGEBANDS, RUNNERS PLASTIC NYLON AND STRETCH FILMS WOVEN AND NON-WOVEN BIG BAG Cable And Computer Scraps PLASTIC PIPE AND PROFILES COPPER CABLE AND ELECTRONICS SCRAPS TEXTILE PRODUCTS PAPER AND CARDBOARD WOOD ALUMINUM

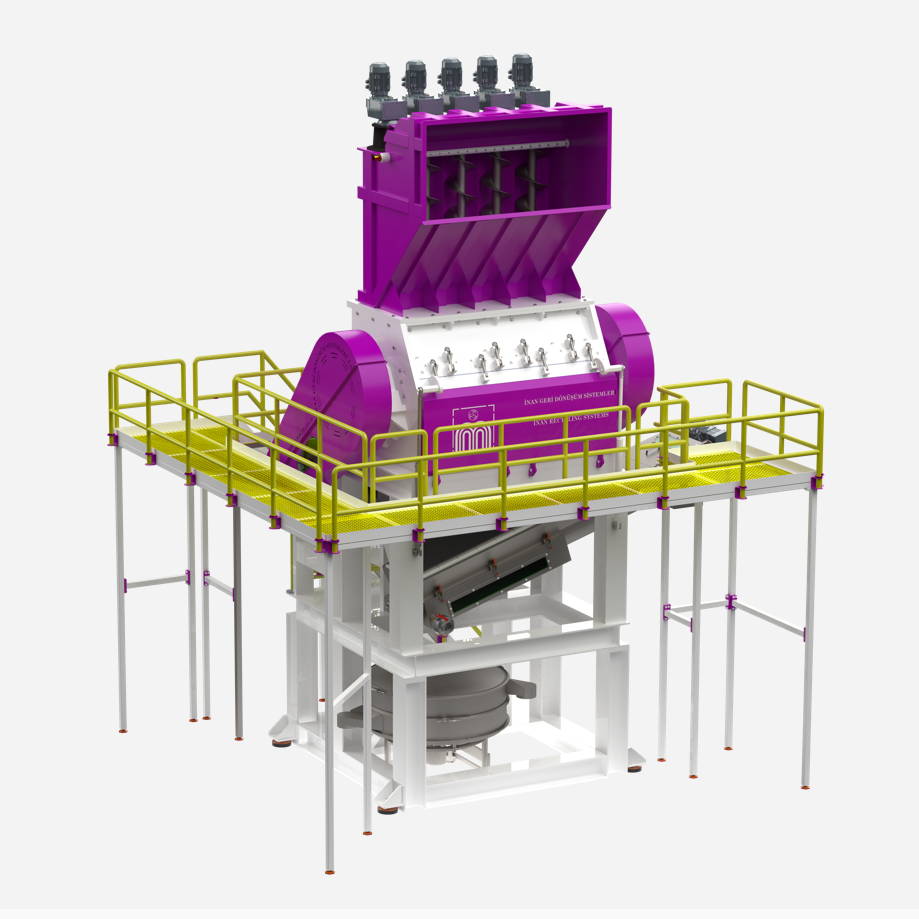

Force Feeder crusher machines, which are specially designed to meet the size reduction demands in recycling facilities, have been produced as a solution to high capacity needs. 5 and 7 rotary rotor blade applications are available. Fixed blades positioned on the body at a TANGENTIAL angle provide greater grip and increase cutting capacity to maximum levels. The crushing chamber is coated with Hardox to protect the body from the corrosive effects of highly abrasive plastics. High performance in size reduction is achieved with the unique rotor blade arrangement, angular positioning and multi-blade rotor star structure. With the FORCE FEEDER funnel design, high performance, homogeneous crushing and long blade life are aimed by feeding plastics directly between fixed and moving blades and ensuring equal use of all blade surfaces.

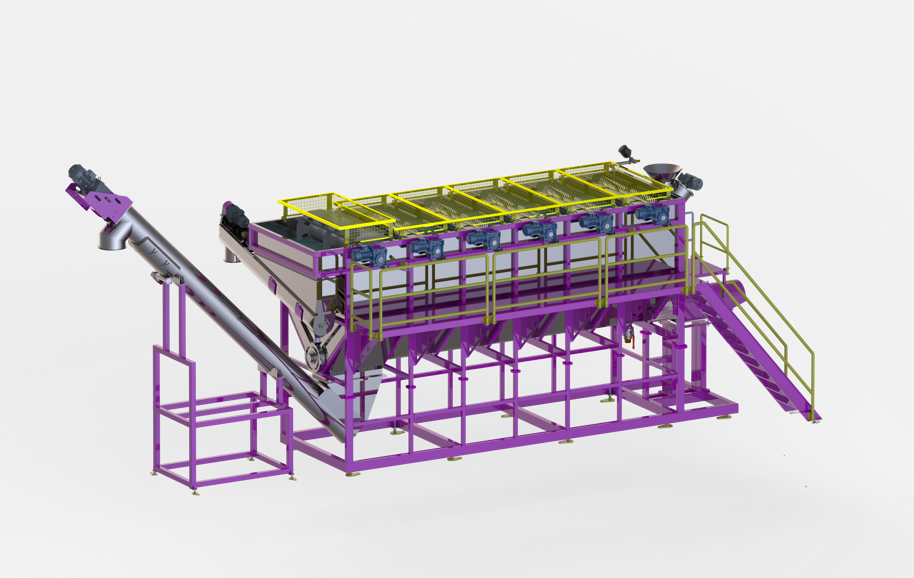

Turbo friction washing machines are one of the important machines used for cleaning the plastic flakes that are washed in washing lines at various stages (Wet Crushing, Floatation & Immersion, Separation Pools, Hot Washing Units, etc.). High speed rotating centrifugal separation rotor (1500-2200 rpm) provides high efficiency and cleanliness and dewatering by providing the centrifugal force without the need of any heat source, separating plastics from contaminants (sludge and other contaminant residues). These systems, which are widely used in recycling lines, can reduce the humidity level to minimum levels while maximizing the washing quality.

Yıkama hatlarında kullanılan havuzlar; boyut küçültme işleminden geçen plastikleri (PET, HDPE, LDPE, PP); toz, toprak, çamur, taş, metal, kâğıt gibi yabancı kirletici maddelerden ayrıştırmak için kullanılan en önemli ayrıştırma ünitelerinden biridir. Karışık plastik, yüksek yoğunluklu malzemelerin battığı ve düşük yoğunluklu malzemelerin yüzeceği tankın içine verilir. Malzeme ayrıştırma havuzuna girerken, özel olarak tasarlanmış döner tamburlarımız malzemeyi ileriye doğru ve su ile taşır. İdeal olarak, malzemenin daha uzun süre suya dalmasını isteriz. Bu sadece malzemenin daha fazla temizlenmesine olanak vermekle kalmaz, aynı zamanda tüm batan malzemelere tankın dibine hareket etmesi için yeterli zaman tanınmasını sağlar. Yoğunluk farkları sebebi ile farklı plastik türleri için değişik tip ve kapasiteye göre de değişik boyutlarda yüzdürme & batırma, ayrıştırma havuzları imal edilmektedir. Yüzdürme & batırma havuzları işlem görecek malzemeye göre özelleştirilmiştir ve hem yüzer hem de batan malzeme için sürekli çalışan deşarj sistemi ile donatılmıştır. Güçlü konstrüksiyon üzerine kurulmuş olan havuzlar, uzun yıllar hizmet verecek şekilde dizayn edilmiş, maksimum temizlik, minimum fire anlayışıyla imal edilmekte ve hattın içinde tamamen otomatik olarak çalışmaktadır.

It is used to wash very dirty plastics for high quality product demands and to remove plastic from contaminants such as glue, label residue, odor, oil, food and beverage residues. Hot washing units have high washing performance with low energy consumption. Hot washing units used in washing lines are suitable for washing PET, HDPE, PP, LDPE etc. plastics.

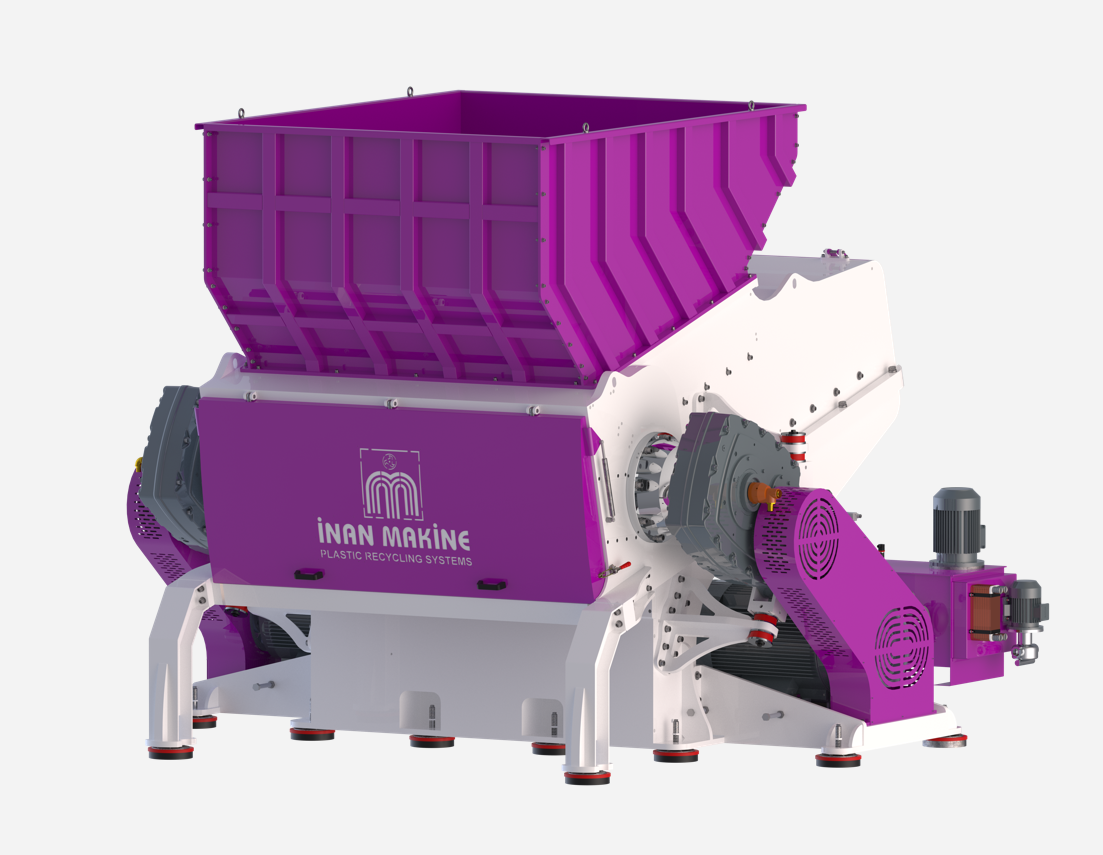

Shreders Machines are designed to be used in size reduction processes by respond to high capacity demands. Enables easy disintegration of Sack, Big-Bag, FILM (Nylon), Car Tire, Pallet, Rope, Pipe etc. plastics and wooden pallet, copper cable etc. materials which are big size or very hard. Rotor type, blade type, pressure unit and screen type can be selected according to the material to be processed. Precise adjustment of blades and rotor profile ensures maximum efficiency. Crushed materials are formed in homogeneous size.

No represented companies found.

The company has no registered brand information.

TR

TR