| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

OĞUZ GERİ DÖNÜŞÜM MAKİNALARI SAN. VE TİC. A.Ş.

İNÖNÜ MAHALLESİ 167 SOKAK NO: 13 TORBALI / / İZMİR / TÜRKİYE

|

Contact Info: +90 232 254 7161

|

Hall: 11

Stand: 1125

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

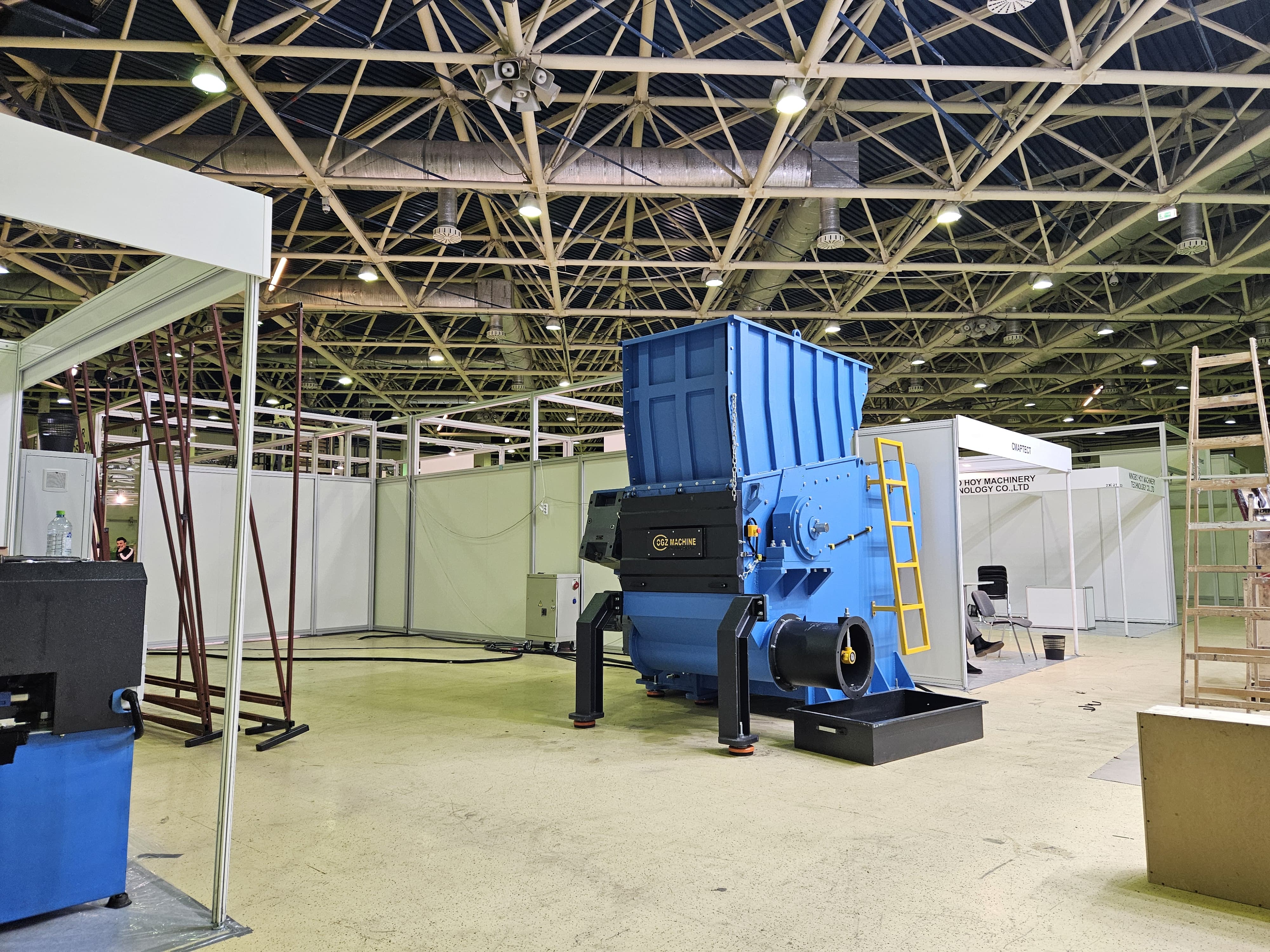

Under the slogan of a greener world, we manufacture the machines required for breaking, washing, squeezing and drying the product in plastic recycling facilities. As Oğuz Makina, we continue our commercial life, which we started in 1995, with the excitement of the first day. We are continuously expanding our production capacity by transforming our earnings into investment. We aim to provide you with faster and higher quality service with our production facility, which we established in an area of 9,000 m2 in 2022. We have taken successful steps in our sector with your support on the path we set out on with the principle of maximum efficiency and minimum cost. We continue our R&D studies uninterruptedly to produce more analytical machines for you with our innovative and rational approach. We manufacture the machines required for breaking, washing, squeezing and drying the product in plastic recycling facilities. We have a spare part stock for each machine assembled in our organization. It is supplied to our customers quickly upon order. Every machine leaving our track is recorded in a digital environment and in case of any malfunctions, it is easily repaired by our service team.

Our crushing machine manufacturing covers a wide range from crushers with a capacity of 100 kg/hour to heavy-duty crushers with a capacity of 5000 kg/hour and above. The design features common to all our crushing machines provide time, labor and energy savings thanks to efficient and trouble-free service, easier and less maintenance. In our plastic crushing machines, materials are crushed with a full scissor movement between rotating and fixed blades positioned at opposite angles to each other. In this way, equal-sized burrs are obtained. This method, which reduces excessive heat and noise generation that reduces the quality of the crushed material, also provides savings in energy consumption.

It shreds wastes such as plastic, nylon, sacks, tires of different sizes. Due to the variable structure of the material such as thickness and hardness in the shredding process, the hydraulic pressure and PLC control unit prevent the machine from being damaged. And it works continuously with high capacity.

Circular blades arranged on two rotors rotate in opposite directions. The hook-shaped wings on the circular blades catch the material and pull it inwards. Meanwhile, the material trapped between the blades rotating in the opposite direction is broken up by the blades acting like scissors. It has low operating costs thanks to the blades made of special alloy steel. The blade model and material are selected according to the type of material to be broken down.

It has an excellent performance in removing solid dirt on plastic thanks to its high impact and friction ability. Horizontal turbo washing centrifuges are produced in different sizes and systems according to the type of plastic. It is also very effective in separating materials such as burrs and labels on PET. It is also highly preferred due to its low energy consumption.

It is used for drying hard burr materials under high speed. Thanks to the specially designed rotor, the moisture content is reduced to 1%-5% depending on the type and size of the material. Thanks to the improved sieve design, easy cleaning and replacement are made. It provides significant contribution to both use and nature with its low energy consumption.

It is used for dewatering washed plastic types such as nylon, sacks, and films by mechanical squeezing. Depending on the type and thickness of the plastic, the output moisture content varies between 4 - 8%. It is not affected by capacity fluctuations in washing lines with its improved screw design. Considering its energy efficiency, operating cost, capacity and ease of use, it is the most efficient system for dewatering nylon, sacks, and films compared to hot air or centrifugal systems. It is resistant to the dynamic power created by the mechanical squeezing process with its high torque extruder type reducer and strong chassis made of heavy duty steel.

No represented companies found.

- OĞUZ GERİ DÖN. MAK. SAN. VE TİC. A.Ş.

TR

TR