| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

POLYTEKPROM TEKNİK MAKİNA İTH.İHR.SAN. VE TİC.LTD.ŞTİ.

NİSBETİYE MAH. GAZİ GÜÇNAR SOK. NO: 4/2 / BEŞİKTAŞ / İSTANBUL / TÜRKİYE

|

Contact Info: +90 533 065 9080

|

Hall: 11

Stand: 1123A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Polytekprom is a leading company specialising in waste management and flexible packaging machines. As Polytekprom, we offer environmentally friendly waste management solutions as well as innovative solutions in the field of industrial packaging. Our company is committed to helping our customers optimise their business processes by providing solutions focused on sustainability, efficiency and quality.

BREAK ONE, with its 4 different models having screen diameters of 400 500 600 700 mm, can provide services in the capacity range of 250 kg/hour 1500 kg/hour. With a minimum filtration fineness of 60 microns, it cleans impurities on the filter surface with 2 scraper blades and drains them using a valve on the filter body.

Break DUO offers high-capacity maximum filtration service with its two laser-perforated screens. Thanks to its patented scraper system, it easily and quickly removes contaminants such as paper, wood, copper, aluminum from the screen surface and drains them. The screw waste discharge maintains a constant output pressure. This ensures no pressure loss after filtration, preventing melt flow fluctuations after the extruder without the need for equipment like gear pumps. By maintaining a steady output pressure, you can preserve your precise flow without using devices such as gear pumps. BREAK DUO also minimizes maintenance time. With its special design, you can change your filters quickly without having to remove the discharge screw or filter support plates.

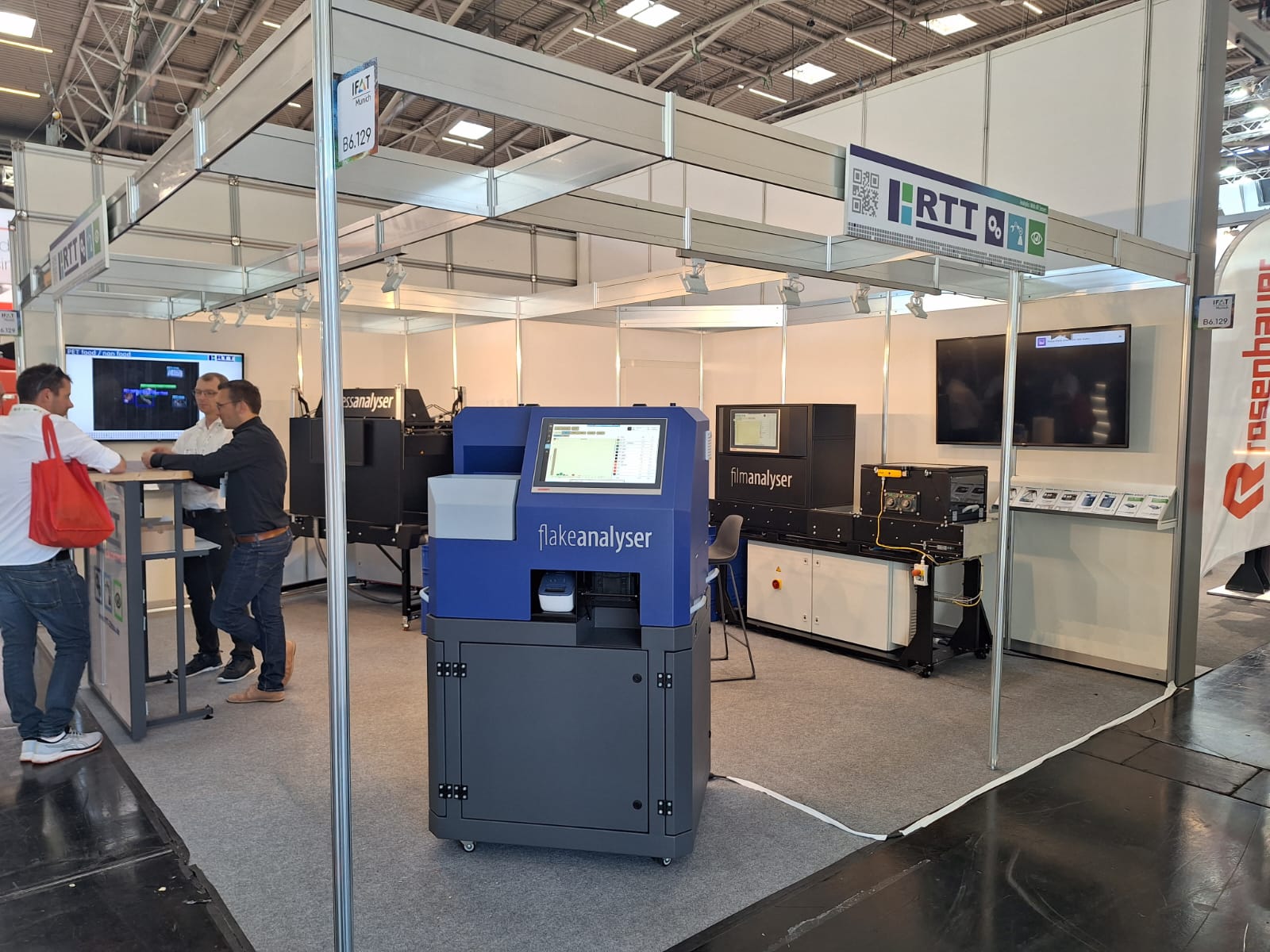

The FlakeAnalyser performs type, color, and size analyses of plastic flakes ranging from 2 to 30 mm in a single stage. With the support of a 3D camera and artificial intelligence, it conducts size, volume, and weight-based analyses of the flakes. The integrated 3D camera provides a comprehensive solution. The type analysis of the flakes is carried out using NIR sensors. The color camera displays the color distribution of the flakes, and it identifies the total proportion of black and dark-colored objects. Thanks to its offline analysis feature, samples taken from different stages of plastic production lines can be tested. It comes with digital integration into a central information system and automatic result archiving features. It is suitable for facilities in recycling, pipe, profile, sheet, cable production lines, as well as blow molding and injection facilities that either produce plastic flakes or use them as raw materials.

It enables real-time color and type analysis of mixed film plastics.

Environmental issues have become one of the greatest challenges humanity faces today. Particularly, the management of plastic waste holds significant importance in preserving nature. Plastic recycling plants reduce the burden on the environment by transforming these wastes into reusable products. However, it is crucial to dispose of the waste water generated during the operation of these plants without harming the environment. It is important to examine the critical role of wastewater treatment systems in plastic recycling plants. The wastewater produced in a plastic recycling plant can cause significant harm to the environment due to the chemicals and harmful components it contains. Discharging these waters into the environment without treatment pollutes water sources, threatens aquatic life, and jeopardizes human health. Wastewater treatment systems clean these harmful substances from the water, thereby protecting natural water sources, balancing ecosystems, and contributing to public health. The wastewater treatment systems used in plastic recycling plants purify wastewater using physical and chemical methods, making it harmless to the environment. Physical treatment processes remove mud, particles, and other solid materials from the water, while chemical treatment processes separate harmful chemical components from the water structure. The function of these wastewater treatment systems is not limited to preserving nature; they also ensure efficient water use. With the decrease in water resources worldwide, effective water use and recycling are of great importance. Wastewater treatment systems enable the reuse of water used in factories, thus managing water resources more efficiently. In conclusion, wastewater treatment systems in plastic recycling plants are crucial for preserving nature, efficiently using water resources, and protecting public health. These systems enable sustainable plastic recycling activities without harming the environment and help achieve the goal of leaving a clean environment for future generations. Therefore, effective implementation of wastewater treatment systems in plastic recycling plants is a critical necessity for both the environment and humanity.

We offer turnkey solutions for post-consumer and post-industrial plastic waste of PE, PP, PET, PS, and ABS types.

- POLYTEKPROM

TR

TR