| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SUZHOU POLYTEC MACHINE CO., LTD

No. 4, Changde Road, Changyinsha Modern Agriculture Demonstration Park, Zhangjiagang City, Jiangsu Province / / / CHINA

|

Contact Info: +86 19 ext. 942085643

|

Hall: 11

Stand: 1127A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Suzhou Polytec Machine Co LTD fouses on the R&D and manufacturing of complete set of weste plasic ecyoling and procsig systems and has provided senices tcustomers in more than 30 countries through high-quality customized solutions, professional real-time technology and after-sales service. The core team of Polytec has more than 15 years of experiencein the formulaton and implementation of overll outions for renewable resources, and has a kee insightinto market dynamicos our company has an independent R&D deparment and a senior fechnical team.Engineers and teachnicians have been engaged in the industry formany years and to accunmulale and master applcaton techm ologes in variou fieds of the industy atach importance to nteraction with partners,regulary assgn engineersto visit production plants in Europe and America,extensively absorb advanced technologies and concepts, and constanty pursue technological inovation. POLYTEC is currently working on four directions 1.Waste plastic cleaning and classification waste plasti fims, bags,barels, boties ,etc.are broken and cleaned, and lesies f oifirent materals are separeted,whichare directly used in downstream industries such as recycled plastic granulation; 2.Recycled granulation of waste plastics recycled granulation after cleaning of factory materials and post-consumer plastics; 3.Development of key machiner for recycling and recycling R&D and manufacturingof key modelsfo diferent materas i ditirentinduties,and provide key equipmentfor various process routes; 4.Waste electronic waste treatment Provide system-wide process design and development and reuse for the growing consumer electronic products. 5. Design and implementation of prject engineering Our company provcdes guidance on plant design layout in the eary stage of th project, and the ovrall isalaion ofon-site water and electricity.

Bottle-to-Bottle grade PET bottle washing line makes the sustainable development of PET bottle resource recovery come true. The global PET resources are being exhausted,but its demand is increasing year by year.The over exploitation of petroleum has caused irreparable damage to the natural and earth,human beings are suffering from nature. Sustainable development of PET resources recovery has been a major issue in the PET recycling industry.Full utilization of PET resources and 100%recovery of PET resources to achieve sustainable development is the ultima goal of recycling.At present,the mainstream process to realize the recycling of PET bottles(containers)is physical recycling.Post-consumer PET bottles are collected from urban,it is recycled into rPET flakes by washing and crushing which rPET flakes can be used to manufacture food-grade chips.This kind of rPET flakes meets the standard of FDA which is available to contact food and beverage directly.

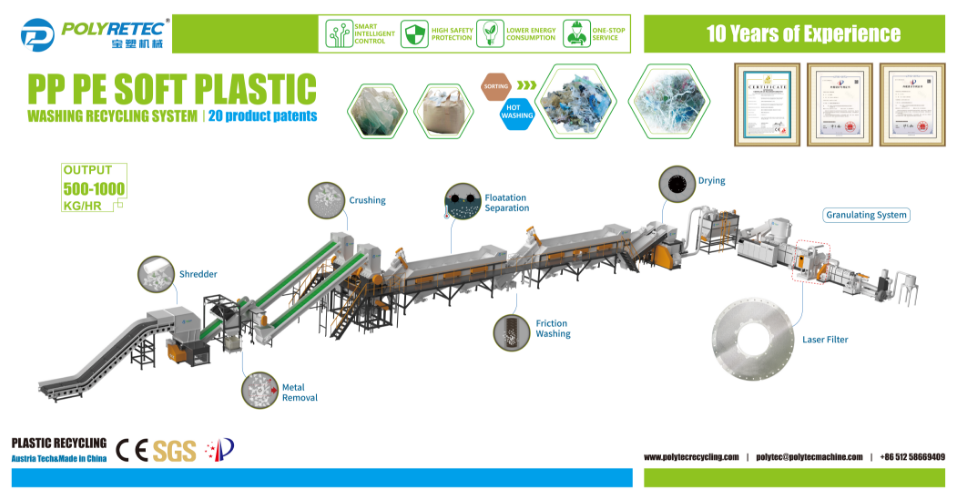

POLYTEC persistently adheres to the design concept of SMART RECYCLING, HIGH-VALUE PLASTICS , concentrating on economy, practicality, and stable performance, continuing to seek breakthroughs in equipment production capacity, power consumption, water consumption, finished product loss rate, and degree of automation. In recent years, by actively absorbing Europe s valuable experience in film (PE) and woven bag (PP) recycling, and combined with our company s many years of waste plastic recycling experience, we Manufactured updated PP/PE floating washing line to realize efficient coarse crushing, fine crushing, washing and discharging, dehydration and semi-plasticization.

No represented companies found.

The company has no registered brand information.

TR

TR