| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

VİKOTECH MAKİNE SANAYİ TİCARET LİMİTED ŞİRKETİ

İkitelli OSB Mahallesi Eski Turgut Özal Caddesi No: 23 C/C Başakşehir / / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 549 1972

|

Hall: 11

Stand: 1123B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

As VikoTech Machinery, considering all these current and future problems, we offer plastic recycling machines and facilities manufacturing services with our highly experienced team members who are experts in their fields. Our founding purpose has been to respect the environment and human beings, and to leave a beautiful future to the world. Within the framework of this purpose, we have placed our focus on our customers. Our belief in high customer satisfaction has continued to increase throughout all these years we have been serving. We are dedicated to improving ourselves with the aim of better meeting our customers needs, In addition to high-performance machines, we have manufactured and continue to manufacture plants that operate smoothly. We are committed to being an expert and leading company in the field of plastic recycling to combat the growing garbage piles on our planet and the pollution of our earth and oceans. We know that the resources of our planet are limited. For this reason, we are aware that how carefully raw materials should be used has become more important than ever. Our company, which is leading the change, works by offering machines and facilities that will contribute significantly to sustainable plastic processing. As a part of sustainable economy, we are moving towards being a leading company in the plastics industry, both nationally and internationally, with our technology and ideas. We always act by sharing our experiences in the light of our mission, vision and values. We establish open and transparent business relationships in all of our business processes. We offer solutions that respect nature and people, which consumes resources efficiently. We are working on discovering new technologies for recycling industry. We carry out R&D studies that always consider innovation and performance. We offer easy-to-reach and fast-solving services. By establishing an agile organizational structure in the corporate structure, we adapt quickly to changing conditions. We are constantly improving ourselves in order to accelerate the production processes of the companies we serve, to increase their efficiency, to reduce their costs and to increase their profit shares to the highest level. We provide opportunities for our employees to improve their knowledge and skills. We reward and encourage excellent work

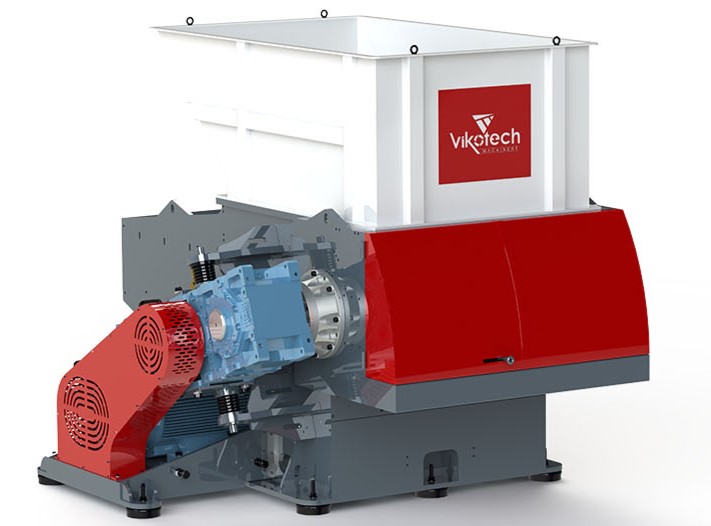

Single Rotor Shredders are used for size reduction of all types and forms of plastic scrap, cardboard, tex- tile, carpet, paper waste without getting affected by thickness and density of material. Rotor, blade, feeder and screen model is chosen according to the type and form of scrap to quarantee high capacity. Straight, inclined or swing type feeders are used for different forms of scrap and feeders can be powered by hydraulic or pneumatic power. Feeders are controlled by PLC system.

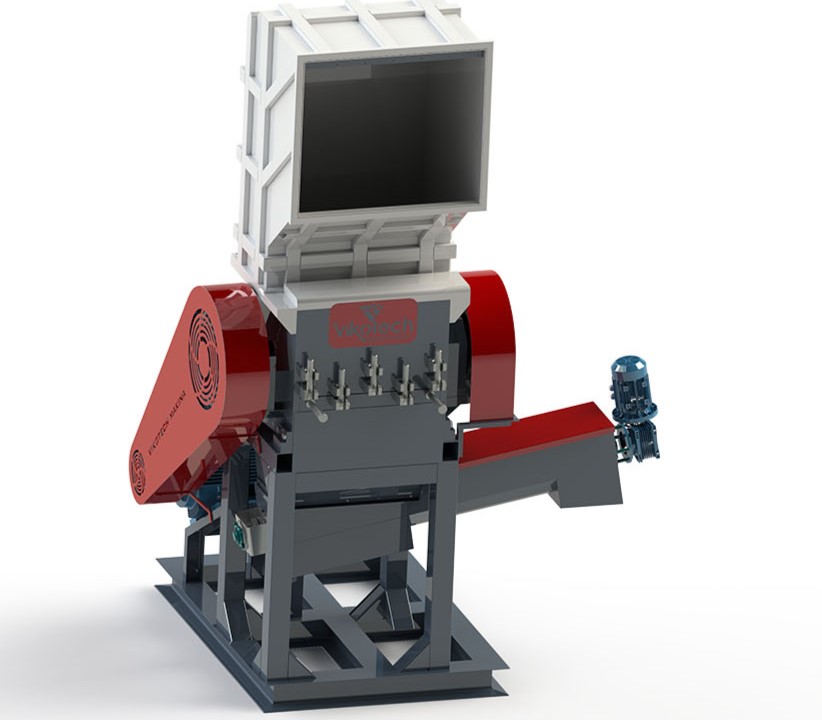

Plastic Granulator machine Crushers one of the key machines used in Plastic Recycling line. Compact body design, special bearings and Powerful Rotor design extends the life of the machine. Granulator machines are manufactured with production capacity starts from 100 kg/h up to 1500 kg/hr.

They are used for separating the floating plastics from contaminants like heavy plastics, mud and metals, Contaminants can be easily discharged by the under-tank discharge valve. Sink & float tanks are designed with maximum cleaning, minimum material loss method. Sink & float tanks can be made of AISI 304 stainless steel or DKP sheet, and length 3000mm-6000mm according to customer s demand.

Horizontal Centrifuges VK-SNT are used for washing plastics under high speed and they clean plastics intensively by friction. Our improved rotor and rotor wings design creates more friction which increases centrifuge efficiency. VK-SNT are made of AISI 304 stainless steel material, and sizes between diameter Ø250-Ø500mm, and length 3000mm-5000mm according to required production capacity.

It s a multifunctional machine that can wash-clean, dry and separates crushed plastics materials such as PE, PP, PET, and LDPE While rotor on centrifuge turns at 1500 rpm the perforated trommel around it turns opposite direction for maximum intensive cleaning. Rotor at high speed with centrifugal principle collects all heavy plastics at bottom of machine and same time all the water and none plastics thrown out from perforated trommel holes. Drying is done mechanically without Reduces moist level less than %1 Trommel holes diameter changeable it depends on process to be Depends on process rotor and trommel speed ranges from 1000-1500 Easy access to trommel cleaning and According to customers request and needs drying and washing capacity range 500kg/hr to 3500 kg/hr

Plastic Film Dewatering Machine is one of the most important machines in Plastic Recycling line. All the crashed and washed contaminated Plastic FILM materials, dewatered by this machine. Material dewatered mechanically and it will not require an operator. Special designed heavy-duty screw and barrel will reduce the humidity level down to 4 8 %, and this will reduce the electricity consumption for next drying phase.

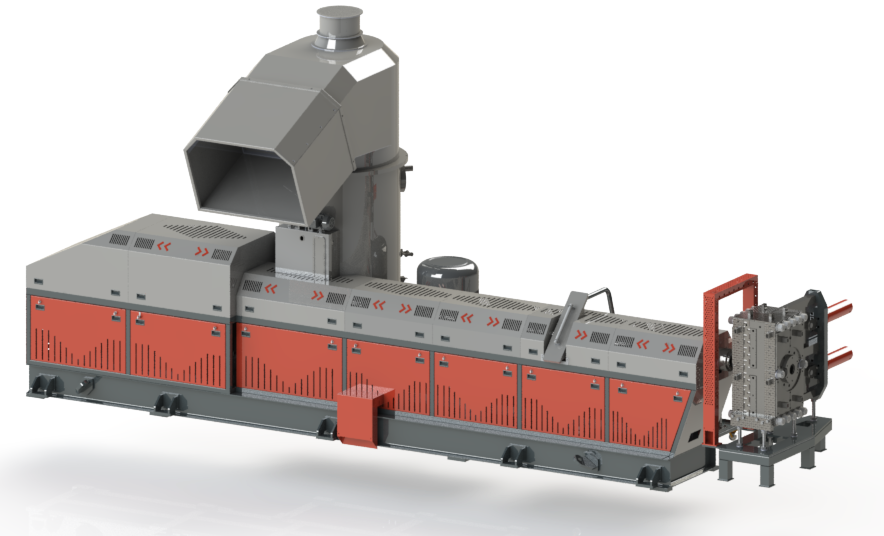

There is a lots of waste plastic in environment such as LDPE, HDPE, LLDPE, PP, OPP, BOPP, CPP, PS, EPS, ABS, after all this plastic waste collected, they will be taken to recycling plants. They will be separated. All the cleaned and dried materials will go to Extruder machine, where becomes a reusable granule. Two-stage extruder machine is working as a machine coupled with the continuation of current extruder. The biggest reason for the preference of this machine during heavy printed plastic production or in cases where it is difficult to release the harmful gases out of the melted plastics, then it is the best granule solution.

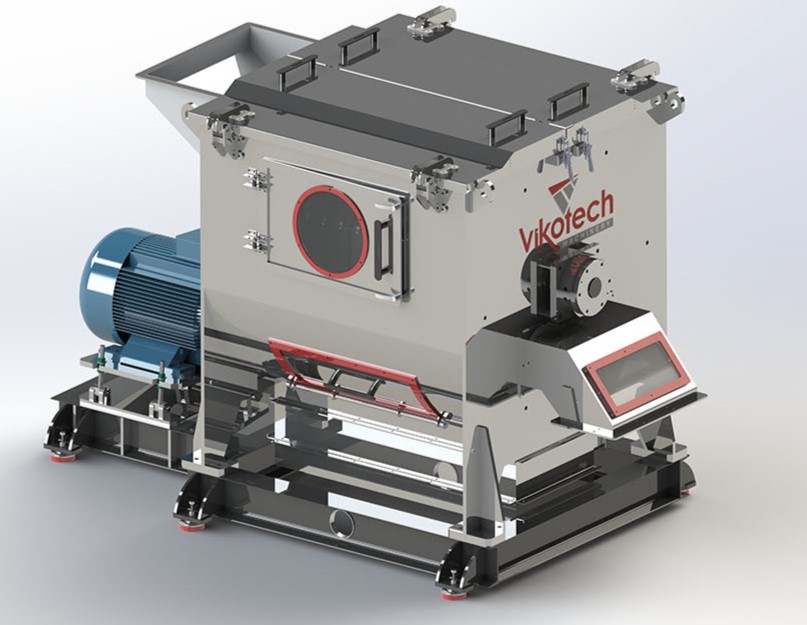

VK- CP extruders process plastic in all forms burr, bran, foam of: LDPE, LLDPE, HDPE, PP, PS, ABS material types. Even plastics with high moisture content up to 7% can be pelletized without problems. The high technical equipment of the VK-CP extruder allows: Final drying, condensation, homogenization & degassing Processes in one step. The VK- CP extruder operates with minimal manpower requirements thanks to its user-friendly PLC control system. With the recipe function, all parameters of the system are recorded. When processing plastics with different properties, different recipes are recorded and all parameters are automatically loaded into the system with just one click.

The pelletizing machine is used to cut the plastic melt that comes out of the extruder and turns it into a small pellet shape. This pelletizer can be used for PP, PE, HDPE, LDPE, ABS, PS and PU materials. The granule size can be adjusted according to customer s requirement. The cutting process is done by horizontal, water-cooled and easily adjustable spring-loaded blade system. Cutting blades are made of 1.2379 steel. Pelletizer are completely made of AISI-304 stainless steel. Easy changeable mirror and the Steel blades. Perfect vertical air system for drying with-in transfer to final storage-silo.

High Performance filter for contaminant discharge. Up to 5% contaminant content Dust, Paper, Wood, Aluminium, etc. Support a wide variety of polymers. Filtration up to 70um. Long screen service life. SCREEN CHANGERS: Automatic screen changer Self-cleaning screen changer Automatic and continuous screen changer FILTERS Automatic melt filter Automatic self-cleaning filter Plastic recycling filter Automatic filtration for plastic recycling and cleaning the contaminants

No represented companies found.

The company has no registered brand information.

TR

TR